Business:

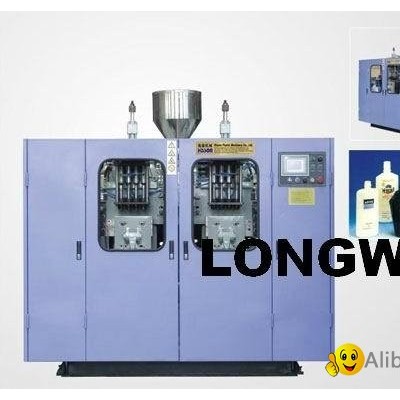

ZHT -II 2L Fully automatic extrusion blow moulding machine(Double station)

- FOB Price:

- Negotiable | Get Latest Price

- Order Quantity:

- 1 Set / Sets

- Supply Ability:

- 1000 Set / Sets per Month

- Port:

- shanghai

- Payment Terms:

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- Delivery Detail:

- 5 days

-

Full Automatic 5 Gallon Filling Machine/

Inquiry -

Aluminum Cap Glass Bottle Rinsing Fillin

Inquiry -

PET Bottle Unscrambler

Inquiry -

SUS304 Design Liquid water Filler

Inquiry -

Pulp juice filling machine ,washer pulp

$15000.00 -

PP,PE bottle making machine/extrusion mo

Inquiry -

tomato , pome pulping machine ,

Inquiry -

Table water Washing Filling Capping Thre

Inquiry

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1、Electrical control system:The machine works under the PLC control(made by the Mitsubishi Co. of Japan) via a man-and-machine interface(displayed in Chinese version or in English version).The machine is equipped with a modularized temperature controller and operated through a touch-type coloure screen.All the production data can be set up,modified,searched and monitored and the machine trouble diagnosis can be completed both on the touch-type screen.The electric elements work on the non-contact working principle,thus being durable in service life. 2、Hydraulic system:The machine works under the proportional pressure control. The machine is equipped with hydraulic valves and hydraulic pumps imported from world-famous companies,thus assuring consistent and reliable working performance. 3、Plasticizing system:The high performance screw used on the machine assures thorough and homogeneous plasticization and mixing of plastics. 4、Speed regulation system:Frequency-converter-controlled speed regulator + speed change gearbox with hardened alloy steel gears.Speed regulation can be completed smoothly with less noise generated.Therefore the machine is durable in service life. 5、Mould opening,closing & moving system:A big 3-point central beam mechanism for opening & closing the mould halves and locking the mould assures balanced distribution of locking force and is free of any deformation after long-time operation.The mould is horizontally moved on linear spherical ball guideways at high traveling accuracy and rapid speed and with less resistance. 6、Air-bolowing needle bracket:The air-blowing needle bracket is of solid L-square design.The sturdy bracket assures smoothness of the product cut. |

-

SODIUM CARBONATE LIGHT

$300.00 -

API 2H Grade 50 Offsho

Inquiry -

Activated Carbon for P

Inquiry -

Silk protein extract p

$50.00 -

Instant pearl extract

$50.00 -

sell dyed black boiled

Inquiry -

sell horse hair horse

Inquiry -

sell bristle mix filam

$3.50 -

Best Quality Chungking

$1.20 -

Pearl powder

Inquiry -

CATTLE OX GALLSTONE

$35.00 -

dry Donkey hides

$11.00 -

Antarctic krill oil wi

Inquiry -

horse mane and horseta

$10.76 -

feed barley

$140.00 -

animal fine hair

$10.00 -

hing qulity of the ho

Inquiry -

Animal Fine Hair

$1.00 -

Bow Hair

$5.00 -

aniaml fine hair

$1.00

- brand:

- Longway

- Set up shop

- Authorized by Alibobo.com, can provide agency service

- Service Introduction

- Authorized product, Internet cloud promotion service integrating certification promotion and procurement inquiry

- Intelligent website construction

- PC terminal + mobile terminal, create a cost-effective corporate website!