inquiry

- Hi,Sign in

- Orders

inquiry

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

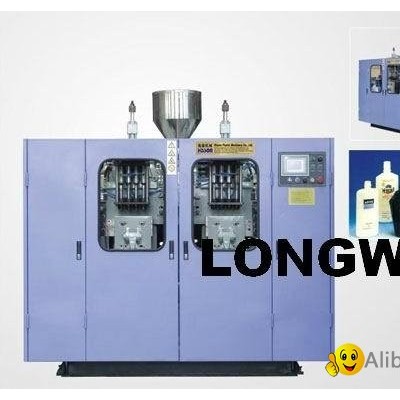

1、Electrical control system:The machine works under the PLC control(made by the Mitsubishi Co. of Japan) via a man-and-machine interface(displayed in Chinese version or in English version).The machine is equipped with a modularized temperature controller and operated through a touch-type coloure screen.All the production data can be set up,modified,searched and monitored and the machine trouble diagnosis can be completed both on the touch-type screen.The electric elements work on the non-contact working principle,thus being durable in service life. 2、Hydraulic system:The machine works under the proportional pressure control. The machine is equipped with hydraulic valves and hydraulic pumps imported from world-famous companies,thus assuring consistent and reliable working performance. 3、Plasticizing system:The high performance screw used on the machine assures thorough and homogeneous plasticization and mixing of plastics. 4、Speed regulation system:Frequency-converter-controlled speed regulator + speed change gearbox with hardened alloy steel gears.Speed regulation can be completed smoothly with less noise generated.Therefore the machine is durable in service life. 5、Mould opening,closing & moving system:A big 3-point central beam mechanism for opening & closing the mould halves and locking the mould assures balanced distribution of locking force and is free of any deformation after long-time operation.The mould is horizontally moved on linear spherical ball guideways at high traveling accuracy and rapid speed and with less resistance. 6、Air-bolowing needle bracket:The air-blowing needle bracket is of solid L-square design.The sturdy bracket assures smoothness of the product cut. |

| The Company | Zhangjiagang Longway Machinery Co. Limited |

| The contact | Yi wen |

| The Address | Luyuan economic development zone, zhangjiagang city ,jiangsu province, P.R China |

| The Website | https://www.alibobo.com/com/zhangj/ |

$20000.00

inquiry

inquiry

inquiry

inquiry

inquiry

inquiry

inquiry

$15000.00

inquiry

inquiry

inquiry

ZHT -II 2L Fully automatic extrusion blow moulding machine(Double station)

Response Rate: High

Avg Response Time: 24–48 h

Business Type: